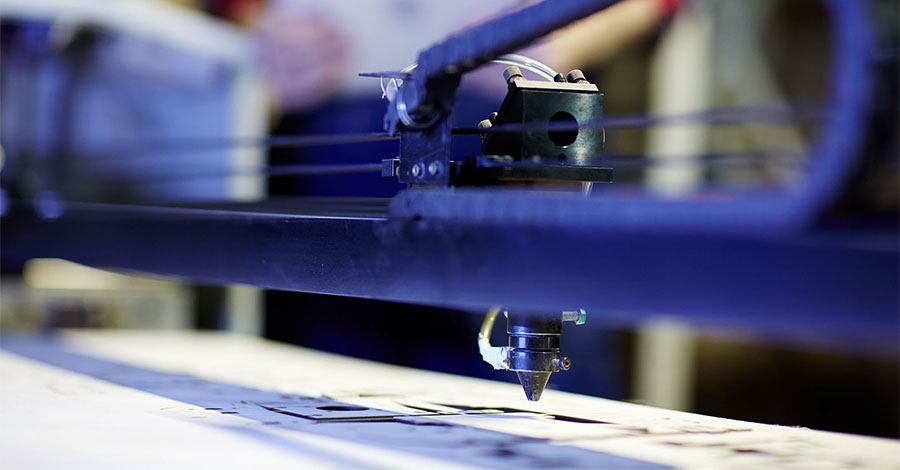

What You Must Consider When Buying A Laser Engraving Machine

In today’s fast-paced world, personalisation and customisation have become increasingly important, not just for individuals but also for businesses. Whether you’re a small business owner looking to add a unique touch to your products or an enthusiast keen on exploring the world of laser engraving, investing in a laser engraving machine is a significant step. However, before you make that purchase, you must consider several crucial factors to ensure you get the right engraving machine.

Purpose & Intended Use

The first and most vital consideration when buying a laser engraving machine is understanding your purpose and intended use. Are you planning to engrave promotional items, create intricate artistic designs, or work on industrial materials? Different laser engravers are designed for various purposes, so knowing your specific requirements will help you narrow down your options. There are plenty of options for a laser etching machine that UK companies can consider purchasing, so look at all options and decide which is best for your business.

Laser Type

Laser engraving machines come in two main types: CO2 and fibre lasers. CO2 lasers are ideal for engraving on wood, acrylic, and glass, while fibre lasers excel at marking metals and plastics. Choosing the right laser type is crucial because it determines the materials you can work with effectively.

Laser Power

The power of the laser is another essential factor to consider. Higher-wattage lasers can engrave and cut through thicker materials and work faster. However, they also come at a higher cost. Assess your material thickness and production speed requirements to determine the appropriate laser power for your application.

Work Area Size

The size of the work area or bed of the laser engraving machine is vital, as it dictates the maximum size of the objects you can engrave or cut. Ensure the engraving machine you choose has a work area that suits your intended projects.

Software Compatibility

Laser engraving machines are operated using specific software. Ensure that the engraving machine you select is compatible with the design software you plan to use. User-friendly software with robust design capabilities can greatly enhance your engraving experience.

Precision & Speed

Consider the precision and speed of the laser engraving machine. High accuracy is crucial for intricate designs, while speed is essential for efficient production. Strike a balance between the two to match your specific needs.

Maintenance & Support

Like any other piece of equipment, laser engraving machines require maintenance. Research the manufacturer’s reputation for reliability and the availability of spare parts. Also, check if they offer customer support and training to help you get the most out of your investment.

Safety Features

Safety should always be a top priority when working with laser engraving machines. Look for engraving machines with safety features such as emergency stop buttons, enclosed work areas, and protective eyewear. Adequate ventilation is also essential to ensure the removal of fumes and debris.

Budget & Cost Of Ownership

Determine your budget before shopping for a laser engraving machine. Remember that the initial cost is just one part of the equation. Consider the ongoing costs, including maintenance, consumables (like laser tubes and lenses), and electricity usage, to calculate the total cost of ownership over time.

Reviews & Recommendations

Before finalising your decision, read reviews and seek recommendations from users who have experience with the machine you’re interested in. Their insights can provide valuable information about real-world performance and any potential issues you might encounter.